- 2 min read

Denk Pharma: Dr. Eck, why is good engineering so important for the production of our products?

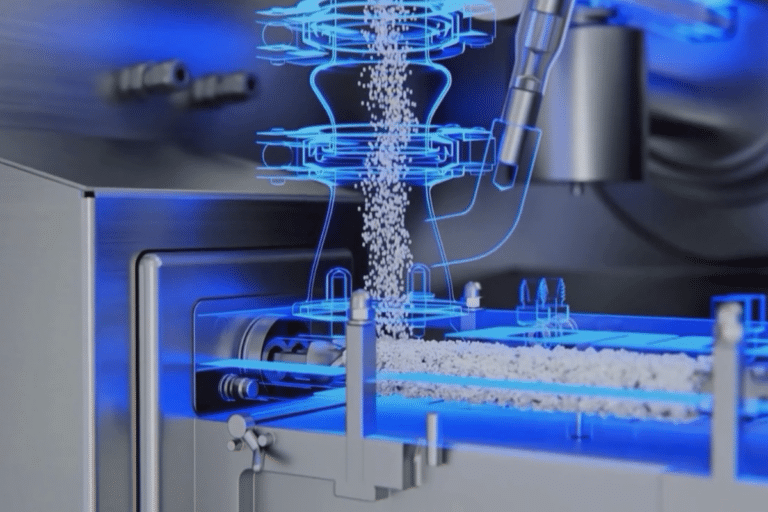

Dr. Kim Eck: To ensure the quality and safety of our pharmaceuticals, it is crucial to have an in-depth understanding of the raw materials, production equipment, and manufacturing process. Awareness of the machines used plays a key role in guaranteeing quality, compliance, consistency, and effective risk management.

Denk Pharma: What challenges can arise in pharmaceutical production and how can high-quality production machines address them?

Dr. Kim Eck: Pharmaceutical production is inherently complex. Particularly when introducing new products or optimising existing ones, a deep understanding of the manufacturing process is essential. Process deviations – unexpected changes or disruptions in production – must be quickly detected and corrected to maintain product quality.

High-quality machines play a central role in this: they help prevent contamination, quality deviations, and inefficiencies. Combined with qualified personnel, tested raw materials, precise documentation, and strict quality controls, they ensure the safety, efficacy, and quality of our pharmaceuticals. This holistic approach guarantees that our products meet the highest standards and optimally fulfil the needs of our patients.

Denk Pharma: How can poor engineering impact the quality and consistency of pharmaceutical products?

Dr. Kim Eck: Poor engineering can result in medications failing to achieve their intended effect or, in the worst case, posing a risk to patient safety.

That is why we strictly adhere to the requirements of Good Manufacturing Practice (GMP).

GMP ensures that production is fully documented and that all necessary analyses and controls are carried out both during the manufacturing process and on the final product.

Only in this way can we guarantee that we bring only high-quality and safe products onto the market.

Denk Pharma: How does compliance with GMP guidelines influence quality assurance and production processes in pharmaceutical manufacturing?

Dr. Kim Eck: GMP, or Good Manufacturing Practice, is a quality assurance system specifically developed for the pharmaceutical industry. Compliance with GMP guidelines is a legal requirement for pharmaceutical manufacturers and covers various aspects such as employee qualification, validation of production processes, monitoring of the production environment, documentation, and quality control of raw materials and finished products. Regular inspections and audits by authorities and independent institutions are an integral part of GMP.